Nexla and Vespa.ai Partner to Simplify Real-Time AI Search Across Hundreds of Enterprise Data Sources

Nexla and Vespa.ai partner to simplify real-time enterprise AI search, connecting 500+ data sources to power RAG, vector retrieval, and AI apps.

Manufacturers rely on data from a wide range of sources—ERP systems, factory equipment, supplier networks, and more. But these systems often don’t connect, making it difficult to access the insights needed for efficient operations.

Nexla solves this by enabling seamless data integration across the manufacturing ecosystem, without heavy engineering effort or expensive IT projects. Our no-code/low-code platform makes it easy to connect, manage, and automate data flows.

Manufacturers typically operate with a mix of legacy ERP systems, modern cloud platforms (SaaS Platforms), IoT-enabled machinery, supplier portals, logistics tools,and much more. These systems often don’t “talk” to each other, leading to:

Inefficiencies in inventory tracking and customer demand forecasting

Nexla is a AI-powered data integration platform that allows manufacturers to easily connect to any data source, transform it, and deliver it where it’s needed—without writing code or building pipelines from scratch.

Whether it’s your ERP (like SAP, Oracle), MES, IoT devices on factory floors, inventory databases, or cloud analytics tools (like Snowflake, BigQuery, or Tableau), Nexla provides pre-built connectors and no-code/low-code tools to integrate systems in days, not months.

✅ Example: Connect your machines’ IoT data to your production planning dashboard in real-time, helping identify bottlenecks instantly.

Once connected, Nexla automates the flow of data between systems. You can set rules, schedules, or real-time triggers to ensure the right data is always in the right place.

✅ Example: Automatically sync supplier lead times with your ERP and update your procurement planning spreadsheets without manual work.

Nexla enables in-stream data transformation so that you get clean, standardized data across systems—no more reconciling mismatched units, time formats, or product codes.

✅ Example: Standardize product SKUs and quality metrics from different factories before sending to your centralized BI tool.

With Nexla’s data product framework, data is not just integrated—it’s packaged into reusable, secure, and compliant data assets that business, IT, partners and data teams can collaborate on.

✅ Example: Create a shared “Production Efficiency” data product that your operations, finance, and supply chain teams can use for analysis and reporting.

We understand that manufacturing doesn’t stop for data problems. Nexla is built for continuous, reliable data operations with:

In an industry where precision, timing, and efficiency are everything, data connectivity is not a luxury—it’s a necessity. Nexla empowers manufacturers to weave their systems together into a seamless digital fabric, unlocking insights, improving operations, and preparing for a smarter, data-first future.

Ready to learn how Nexla can help your manufacturing business?

Let’s connect!

Nexla and Vespa.ai partner to simplify real-time enterprise AI search, connecting 500+ data sources to power RAG, vector retrieval, and AI apps.

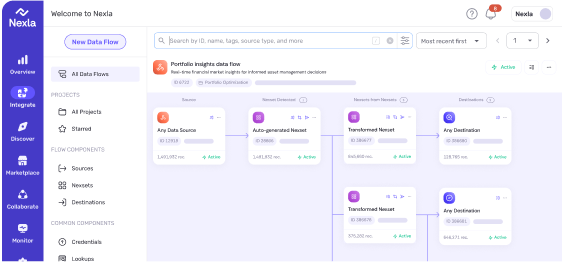

Nexla and Vespa.ai partnership eliminates data integration complexity for AI search and RAG applications. The Vespa connector delivers zero-code pipelines from 500+ sources to production-grade vector search infrastructure.

Reusable data products unify databases, PDFs, and logs with metadata, validation, and lineage to enable join-aware RAG retrieval for reliable GenAI applications.